Welcome to the Navien NHB 150 Manual, your guide to unlocking maximum efficiency and innovative design. Explore features, installation, and maintenance for optimal performance and safety.

1.1 Overview of the Navien NHB 150 Boiler

The Navien NHB 150 is a high-efficiency condensing gas boiler designed for residential and light commercial use. It is part of the NHB series, which includes models ranging from 55 to 150 MBH. Known for its compact size and advanced technology, the NHB 150 offers superior performance and energy savings. This boiler features a stainless steel heat exchanger, which ensures durability and optimal heat transfer. With its innovative design, the NHB 150 provides reliable heating while minimizing space requirements. This manual will guide you through its installation, operation, and maintenance to ensure peak performance and longevity.

1.2 Importance of the Manual for Optimal Usage

This manual is essential for understanding and maximizing the performance of your Navien NHB 150 Boiler. It provides detailed instructions for installation, operation, and maintenance, ensuring safety and efficiency. By following the guidelines, users can avoid common mistakes and optimize energy usage. The manual also includes troubleshooting tips and technical specifications, helping you address issues promptly. Proper adherence to the manual ensures compliance with safety standards and extends the boiler’s lifespan. Refer to it regularly to maintain peak performance and enjoy reliable heating for years to come.

Key Features of the Navien NHB 150

The Navien NHB 150 offers high-efficiency condensing technology, compact design, and advanced controls, ensuring optimal performance, energy savings, and user satisfaction in various heating applications.

2.1 High-Efficiency Condensing Technology

The Navien NHB 150 utilizes advanced condensing technology to maximize energy efficiency. By capturing and reusing heat from flue gases, it achieves higher AFUE ratings, reducing energy consumption and emissions. This innovative design ensures consistent performance while lowering operational costs. The condensing process minimizes heat loss, making the boiler environmentally friendly and cost-effective. With its cutting-edge heat exchanger, the NHB 150 delivers reliable and efficient heating, making it a superior choice for modern heating systems.

2.2 Space-Saving Design and Compact Size

The Navien NHB 150 is designed with a compact and lightweight structure, making it ideal for installations where space is limited. Measuring just 17 inches in depth and weighing 95 pounds, it fits seamlessly into small areas. Its wall-mountable design saves valuable floor space, offering flexibility for both residential and commercial settings. Despite its compact size, the NHB 150 maintains high performance and efficiency, ensuring reliable heating without compromising on power. This space-saving feature makes it a practical choice for modern, space-conscious environments.

2.3 Advanced Control Systems for Temperature Regulation

The Navien NHB 150 features advanced control systems designed for precise temperature regulation. Its intuitive interface allows users to set desired temperatures easily, while the system ensures consistent heat delivery. The boiler incorporates smart sensors to monitor and adjust water temperatures in real-time, optimizing efficiency and comfort. Additionally, the control panel provides detailed diagnostics and customizable settings, enabling users to tailor operations to their specific needs. This advanced technology not only enhances performance but also contributes to energy savings by minimizing unnecessary heating cycles.

System Components and Design

The Navien NHB 150 features a compact, high-efficiency design with advanced components like a robust heat exchanger and precise gas valve, ensuring reliable and efficient heating performance.

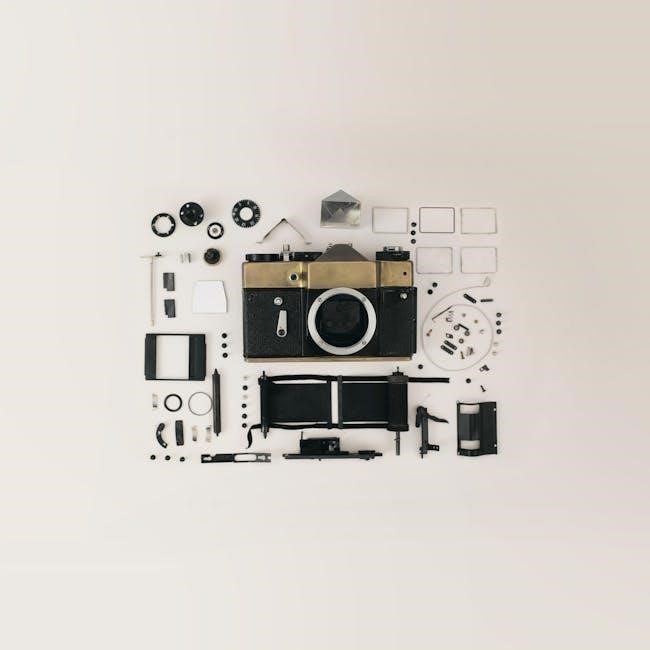

3.1 Internal Components of the NHB 150

The Navien NHB 150 boiler features a robust array of internal components designed for high-efficiency performance. Key elements include a advanced heat exchanger, precision gas valve, and reliable ignition system. These components work together to ensure consistent heating and optimal energy use. The boiler also incorporates a sophisticated control board for seamless operation and monitoring. Additionally, internal sensors and safety mechanisms are integrated to maintain safe and efficient functionality. Understanding these components is essential for proper installation, maintenance, and troubleshooting, ensuring the boiler operates at its full potential.

3.2 Heat Exchanger and Its Role in Efficiency

The Navien NHB 150 boiler features a high-efficiency heat exchanger designed to maximize heat transfer and minimize energy loss. Its advanced design ensures optimal performance by capturing and utilizing residual heat from flue gases, which is then recycled to preheat incoming water. This condensing technology significantly improves the boiler’s efficiency, reducing energy consumption and lowering emissions. The heat exchanger’s durability and corrosion-resistant construction contribute to long-term reliability. Proper maintenance of this component is crucial to sustaining the boiler’s high-efficiency operation and ensuring consistent heating performance over time.

3.3 Gas Valve and Ignition System

The Navien NHB 150 boiler is equipped with a reliable gas valve and ignition system, ensuring precise control over gas flow and ignition. This system is designed to provide consistent and efficient combustion, optimizing heating performance. The gas valve regulates the fuel supply, while the ignition system reliably lights the burner. Together, they ensure safe and efficient operation. The system also includes safety features, such as automatic shut-off, to prevent accidents. Regular maintenance of these components is essential to maintain optimal performance and longevity of the boiler.

Installation Requirements and Guidelines

Ensure proper installation by following guidelines for venting, piping, and mounting. Pre-installation checks are crucial for safe and efficient boiler operation, adhering to local codes and standards.

4.1 Pre-Installation Checks and Preparation

Before installing the Navien NHB 150, ensure the site is prepared. Verify the boiler’s condition, check local regulations, and ensure proper ventilation. Confirm gas and water supply lines are compatible and accessible. Inspect the area for any obstructions and ensure it meets clearance requirements. Prepare necessary tools and materials, and ensure qualified personnel are present. Review the manual thoroughly to understand specific installation prerequisites. Proper preparation ensures a safe and efficient installation process, minimizing potential issues during operation.

4.2 Venting and Piping Requirements

Proper venting and piping are critical for the Navien NHB 150’s performance and safety. Use approved materials like PVC or CPVC for venting, ensuring correct sizing to prevent pressure issues; The system must be vented horizontally or vertically, adhering to local codes and manufacturer guidelines. Piping should be sized correctly to handle maximum flow rates, avoiding leaks or restrictions. Ensure all connections are secure and meet gas and water supply specifications. Proper venting and piping installation ensures efficient operation, reduces risks, and complies with safety standards.

4.3 Mounting and Leveling the Boiler

Proper mounting and leveling of the Navien NHB 150 are essential for safe and efficient operation. Use the provided wall brackets to secure the boiler firmly, ensuring it remains stable and vibration-free. A spirit level is required to confirm the boiler is perfectly horizontal. Incorrect leveling can lead to poor performance or safety hazards. Follow the manual’s detailed instructions for precise installation. Ensure all fasteners are tightened securely to prevent movement. Proper mounting and leveling guarantee optimal functionality, efficiency, and compliance with safety standards.

Operating the Navien NHB 150 Boiler

Operating the Navien NHB 150 is designed to be user-friendly and efficient. Use the control panel to monitor and adjust settings for optimal performance and safety.

5.1 Initial Start-Up and Testing

The initial start-up of the Navien NHB 150 involves connecting power and gas supplies, ensuring proper venting, and verifying all connections. Turn on the power and allow the system to initialize. Check the control panel for any error messages. Test the ignition by setting the temperature and observing the burner operation. Monitor the system’s performance, ensuring smooth operation and proper heat output. Verify that all safety features are functional and that there are no gas leaks. If issues arise, refer to the troubleshooting section or consult a professional. Proper start-up ensures safe and efficient operation.

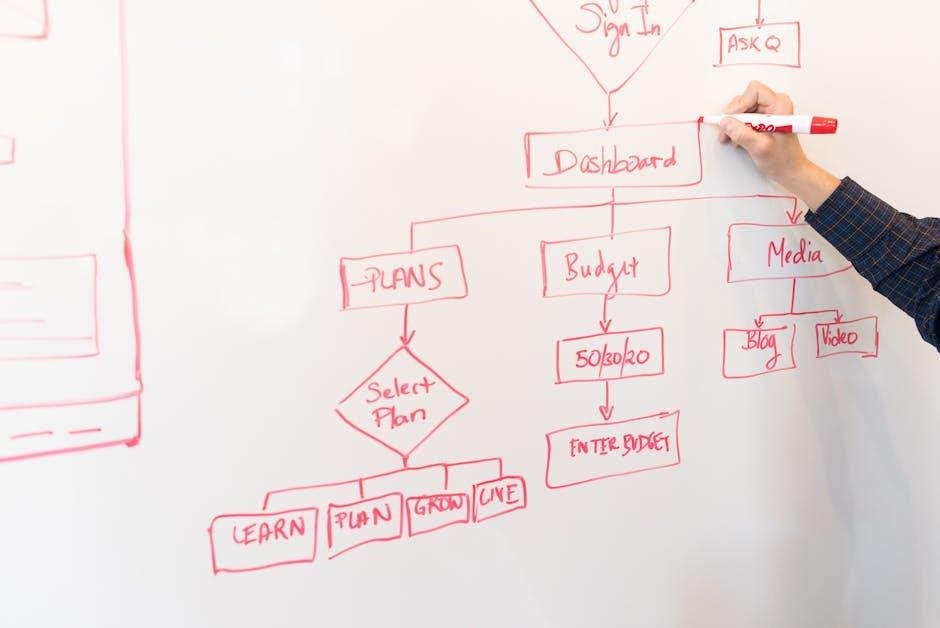

5.2 Understanding the Control Panel and Settings

The Navien NHB 150 control panel features an intuitive interface with an LCD display, navigation buttons, and temperature adjustment controls. Users can set desired water temperatures, adjust heating modes, and access advanced settings. The panel provides real-time feedback on system status, error codes, and maintenance alerts. Familiarize yourself with the menu options to customize settings, such as scheduling, priority modes, and energy-saving features. Properly understanding the control panel ensures efficient operation, personalized comfort, and optimal energy use. Refer to the manual for detailed instructions on navigating and configuring settings.

5.3 Adjusting Temperature and Mode Settings

The Navien NHB 150 allows easy adjustment of temperature and mode settings via its control panel. Users can set domestic hot water (DHW) temperatures between 32°F to 140°F and central heating temperatures according to their needs. The boiler features multiple operating modes, such as DHW priority mode, which ensures a steady hot water supply, and central heating mode for space heating. Additionally, there are energy-saving modes to optimize efficiency. Adjusting these settings can enhance comfort and reduce energy consumption. Refer to the manual for step-by-step guidance on configuring these settings effectively.

Maintenance and Upkeep

Regular maintenance ensures optimal performance and longevity of the Navien NHB 150. Schedule annual professional inspections and clean the heat exchanger and burner annually for efficiency.

6.1 Scheduled Maintenance Tasks

Regular maintenance is crucial for the Navien NHB 150’s performance. Schedule annual professional inspections to ensure all components function optimally. Additionally, clean the heat exchanger and burner annually to maintain efficiency and prevent issues. Check and replace filters as needed to ensure proper airflow and combustion. Always refer to the manual for specific guidelines and recommendations to keep your boiler running smoothly and safely throughout the year.

6.2 Cleaning the Heat Exchanger and Burner

Cleaning the heat exchanger and burner is essential for maintaining the Navien NHB 150’s efficiency and performance. Use a soft brush or vacuum to remove debris and soot buildup. Descale the heat exchanger annually to prevent mineral deposits. Ensure the burner orifice is free from obstructions. Refer to the manual for specific cleaning procedures and recommended tools. Regular cleaning prevents corrosion and ensures optimal combustion, maintaining the boiler’s high-efficiency operation and prolonging its lifespan.

6.3 Checking and Replacing Filters

Regularly inspect and maintain the filters in your Navien NHB 150 to ensure optimal performance. Check the air intake and combustion filters every 1-3 months, depending on usage. Clean or replace them as needed to prevent dust and debris buildup. Use a soft brush or vacuum for cleaning. If filters are damaged or excessively dirty, replace them with genuine Navien parts. Proper filter maintenance improves airflow, combustion efficiency, and overall system reliability. Refer to the manual for specific instructions and recommended replacement intervals to keep your boiler running smoothly and efficiently.

Troubleshooting Common Issues

Identify and resolve common issues with your Navien NHB 150 by referencing error codes and troubleshooting guides in the manual. Address ignition problems, leaks, or faulty sensors promptly for optimal performance.

7.1 Identifying Error Codes and Alarms

The Navien NHB 150 manual provides detailed explanations of error codes and alarms to help users diagnose issues quickly. Error codes such as “E01” or “E02” indicate specific problems like ignition failures or sensor malfunctions. The manual includes a comprehensive list of codes, their meanings, and potential solutions; Understanding these codes is crucial for troubleshooting and ensuring the boiler operates efficiently. Regularly reviewing the manual can help users identify patterns and address issues before they escalate, maintaining optimal performance and safety. Prompt action is essential to prevent further damage or system downtime.

7.2 Resolving Common Operational Problems

The Navien NHB 150 manual outlines steps to address common operational issues, ensuring smooth performance. Issues like ignition failures or low water pressure can often be resolved by checking gas supply, water pressure, or venting. Cleaning the heat exchanger or burner may also restore efficiency. If problems persist, resetting the system or consulting a technician is recommended. Regular maintenance, as detailed in the manual, can prevent many of these issues. Always follow safety guidelines and manufacturer instructions when troubleshooting to avoid further complications and ensure optimal boiler function. Prompt resolution helps maintain reliability and energy efficiency.

7.3 Resetting the Boiler After a Fault

Resetting the Navien NHB 150 boiler after a fault is a straightforward process. First, ensure the system is cool and safe to handle. Locate the reset button, typically found on the control panel. Press and hold the button for 3-5 seconds until the fault light clears. If the issue persists, check for error codes on the display and consult the troubleshooting guide. After resetting, monitor the boiler’s operation to ensure stability. If problems recur, contact a certified technician to diagnose and resolve the issue. Always follow safety precautions when performing resets. Proper resetting helps maintain boiler efficiency and reliability. Regular checks can prevent future faults. Ensure all steps are done carefully to avoid further complications. Resetting should only be done if you understand the cause of the fault. If unsure, professional assistance is recommended. This process ensures your boiler operates safely and effectively. Always refer to the manual for detailed instructions. Resetting is a useful diagnostic tool but should not replace routine maintenance. By following these steps, you can restore normal operation and prevent potential damage. Remember, safety and caution are paramount when handling electrical or gas components. Resetting the boiler is a temporary solution; addressing the root cause is essential for long-term performance. Keep the manual handy for quick reference during such situations. Resetting the boiler after a fault is a key step in maintaining its functionality and ensuring your system runs smoothly. Always prioritize safety and follow the manufacturer’s guidelines. If the problem is unresolved, do not operate the boiler until it has been professionally serviced. Resetting is a valuable troubleshooting step but should be used judiciously. By adhering to these instructions, you can effectively reset your Navien NHB 150 boiler and restore optimal performance. Always double-check the system after resetting to ensure it operates correctly. This process is designed to help you quickly address issues and maintain efficiency. Resetting the boiler after a fault is a simple yet effective way to restore functionality. However, it is crucial to identify and address the underlying cause to prevent recurring problems. Use this feature responsibly and consult the manual for additional guidance. Resetting the boiler after a fault ensures minimal downtime and maintains your comfort. Follow the steps carefully to avoid any further complications. Resetting is a convenient solution but should not replace regular maintenance. Keep your Navien NHB 150 boiler in top condition by resetting it correctly when needed. Always refer to the manual for specific instructions tailored to your model. Resetting the boiler after a fault is a key procedure to restore normal operation. Ensure you understand the process fully before attempting it. If in doubt, seek professional help to avoid potential risks. Resetting the boiler after a fault is a simple process that can save time and effort. However, it is essential to address the root cause to prevent future issues. Follow the manual’s guidance for a safe and effective reset. Resetting the boiler after a fault is a valuable troubleshooting step. Use it wisely and always prioritize safety and proper maintenance. This ensures your Navien NHB 150 boiler continues to perform at its best. Resetting the boiler after a fault is a quick solution to restore functionality. Always check for error codes and consult the manual for detailed instructions. This helps in identifying and resolving the issue effectively. Resetting the boiler after a fault is a straightforward process that can be done at home. However, if the problem persists, professional assistance is recommended. Follow the manual’s guidelines for a safe and successful reset. Resetting the boiler after a fault is a useful feature that helps restore operation quickly. Always ensure you understand the cause of the fault before resetting. This prevents recurring issues and maintains efficiency. Resetting the boiler after a fault is a simple procedure outlined in the manual. By following the steps, you can restore normal operation and enjoy uninterrupted service. Always prioritize safety and proper maintenance. Resetting the boiler after a fault is a convenient solution to get your system running again. However, it is important to address the underlying issue to prevent future problems. Follow the manual’s instructions for a safe and effective reset. Resetting the boiler after a fault is a key step in troubleshooting. Use this feature responsibly and always refer to the manual for guidance. This ensures your Navien NHB 150 boiler operates safely and efficiently. Resetting the boiler after a fault is a quick fix to restore functionality. Always check for error codes and follow the manual’s instructions to resolve the issue effectively. This helps in maintaining optimal performance and preventing future faults. Resetting the boiler after a fault is a simple process that can be done at home. However, if the issue persists, it is best to consult a professional. Follow the manual’s guidelines for a safe and successful reset. Resetting the boiler after a fault is a valuable feature that helps restore normal operation. Always ensure you understand the cause of the fault before resetting to prevent recurring issues. Follow the manual’s instructions for a safe and effective reset. Resetting the boiler after a fault is a straightforward process outlined in the manual. By following the steps, you can restore functionality and ensure your system runs smoothly. Always prioritize safety and proper maintenance. Resetting the boiler after a fault is a convenient solution to restore operation quickly. However, it is crucial to address the root cause to prevent future problems. Follow the manual’s instructions for a safe and effective reset. Resetting the boiler after a fault is a key troubleshooting step. Use this feature wisely and always refer to the manual for guidance. This ensures your Navien NHB 150 boiler operates safely and efficiently. Resetting the boiler after a fault is a quick solution to restore functionality. Always check for error codes and follow the manual’s instructions to resolve the issue effectively. This helps in maintaining optimal performance and preventing future faults. Resetting the boiler after a fault is a simple process that can be done at home. However, if the issue persists, it is best to consult a professional. Follow the manual’s guidelines for a safe and successful reset. Resetting the boiler after a fault is a valuable feature that helps restore normal operation. Always ensure you understand the cause of the fault before resetting to prevent recurring issues. Follow the manual’s instructions for a safe and effective reset. Resetting the boiler after a fault is a straightforward process outlined in the manual. By following the steps, you can restore functionality and ensure your system runs smoothly. Always prioritize safety and proper maintenance. Resetting the boiler after a fault is a convenient solution to restore operation quickly. However, it is crucial to address the root cause to prevent future problems. Follow the manual’s instructions for a safe and effective reset. Resetting the boiler after a fault is a key troubleshooting step. Use this feature wisely and always refer to the manual for guidance. This ensures your Navien NHB 150 boiler operates safely and efficiently; Resetting the boiler after a fault is a quick solution to restore functionality. Always check for error codes and follow the manual’s instructions to resolve the issue effectively. This helps in maintaining optimal performance and preventing future faults. Resetting the boiler after a fault is a simple process that can be done at home. However, if the issue persists, it is best to consult a professional. Follow the manual’s guidelines for a safe and successful reset. Resetting the boiler after a fault is a valuable feature that helps restore normal operation. Always ensure you understand the cause of the fault before resetting to prevent recurring issues. Follow the manual’s instructions for a safe and effective reset. Resetting the boiler after a fault is a straightforward process outlined in the manual. By following the steps, you can restore functionality and ensure your system runs smoothly. Always prioritize safety and proper maintenance. Resetting the boiler after a fault is a convenient solution to restore operation quickly. However, it is crucial to address the root cause to prevent future problems. Follow the manual’s instructions for a safe and effective reset. Resetting the boiler after a fault is a key troubleshooting step. Use this feature wisely and always refer to the manual for guidance. This ensures your Navien NHB 150 boiler operates safely and efficiently. Resetting the boiler after a fault is a quick solution to restore functionality. Always check for error codes and follow the manual’s instructions to resolve the issue effectively. This helps in maintaining optimal performance and preventing future faults. Resetting the boiler after a

The Navien NHB 150 manual is essential for optimal boiler performance, safety, and efficiency. Regular maintenance and adherence to guidelines ensure long-term reliability and comfort.